Regular Trust volunteers continue to brave the cold weather, and the unceasing demands to drink more tea and eat more cake. Richard, our guest blogger, has already described his dogged determination to release the control system – ultimately crowned with success. Meanwhile, Toby was finishing his storage compartment in Coach 7, which effectively completes the body project (though nothing in the heritage business is ever really completely finished – to enhance its current role as a staff facility, even more storage is planned inside the coach, as you can never have too much [as IKEA® will tell you]). Wherever the Rolling Stock Group ends up, we have a ready-made, portable (well – on wheels, anyway) combined tea room/pub/meeting room ready to go. As recently announced in the Trust Newsletter, we have run out of space, and, quite soon, out of time at the present premises, so we are now looking for somewhere else to continue the Rolling Stock Group and Heritage Train Project work. Ideally, we’ll need substantial covered accommodation, in or near to the Blyth Valley, with road access, power and other services – but we will consider anything (although one must bear in mind that the Trust has limited funds, so cannot realistically afford full commercial costs): so if anyone reading this has any suggestions (or lives at a farm with a very large, empty barn), please let us know

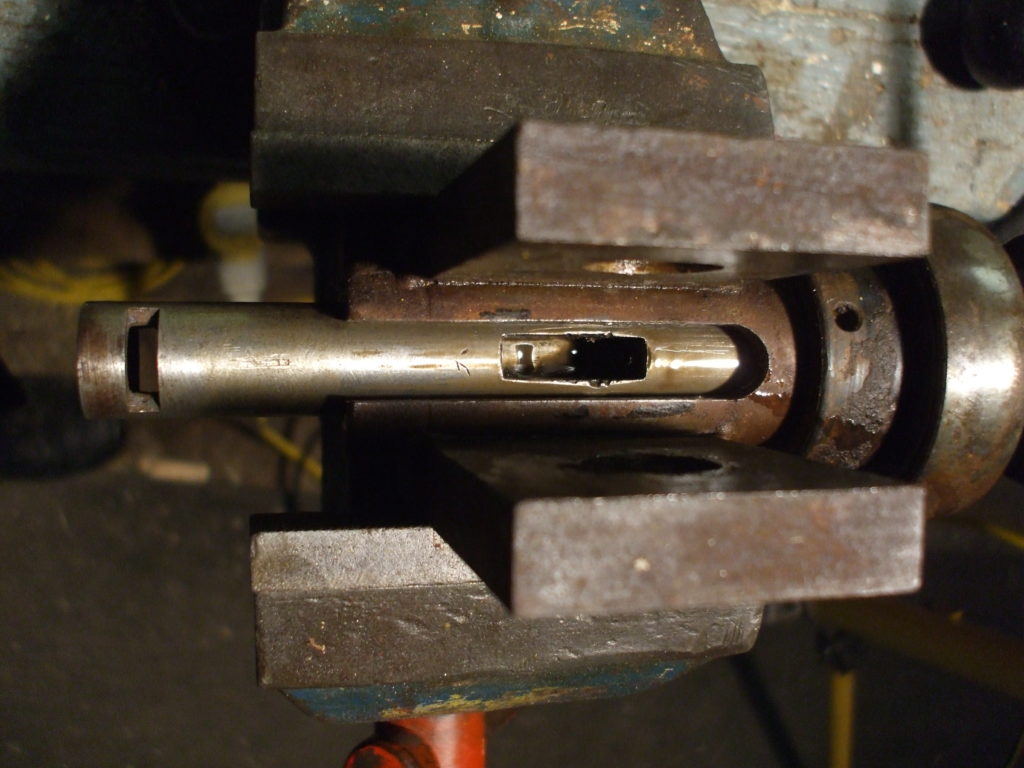

Further with the Motor Rail loco, our electrical specialist John has identified the wiring on the alternator that needs renewal – well – basically – all of it, while Bob – as determined as ever, and undaunted by his losing fight with the loco (the trick is – not to head-butt it), succeeded after much tribulation in withdrawing the (slightly bent) brake shoe hanger pivot. There seems to be an interesting dichotomy between the extremely heavy and robust brake shoes and adjusters, and the quite lightweight pivots on which the entire assembly hangs – one wonders exactly what Motor Rail were thinking of 45 years ago. Anyway – after some weeks of struggle, the brake assembly is off! Not only that, but the various pins and bolts can be copied for the (missing) other side. Now, we can clean it all up, replace rusted retaining pins with stainless ones, and, as soon as the newly-manufactured sanding gear is back from Peggs of Aldeburgh, and attached, both sets of brake gear can be re-attached and adjusted.

The injectors will soon be removed, examined, cleaned, adjusted, and replaced, the remaining fuel drained, filters replaced as necessary, and we’ll find ourselves ready to buy a very large and expensive battery, clamp it on the new (still to be made) battery tray assembly, check that the fuel switch-off works, and then fire up the beast. In fact, there’s quite a bit more to do, not least the electrical wiring – but it’ll be nice to be putting things on rather than taking them off.

Regular readers will probably sigh at this stage, but I do not apologise for again requesting that more volunteers join us. Although the workshops are, for insurance reasons, members-only, this is easily dealt with, and the sheer range of activities has something for the most jaded palate. The team is working simultaneously, on and off-site, on two locomotives (one steam, “Blyth”, and one diesel, “Mells”), and Coach 7: very soon we will be starting on high-end open wagon No 41, and not too far ahead is completing the preliminary work on SR balcony brake composite coach 8. We still have quite a bit of work to do on the ex-Bressingham rails, and keeping the workshop in good condition is a continuing task. The workshop also doubles as an out-station for the Wenhaston group: for example, all the original SR fencing has been mended in-house before being re-erected at the trackside. We now have four scheduled workdays per month for RSG, and enthusiasts have been known to arrange extras as well, to finish or move on particularly interesting jobs. Contact details are on this website.