Wednesday January 27th was, luckily, nowhere near as wet as forecast (they don’t call this the Sunshine Coast for nothing!), so we were able, with a large and enthusiastic team, to split into three. Before that, we collected two large

Looking Forward to 2016, and Launching a New Project

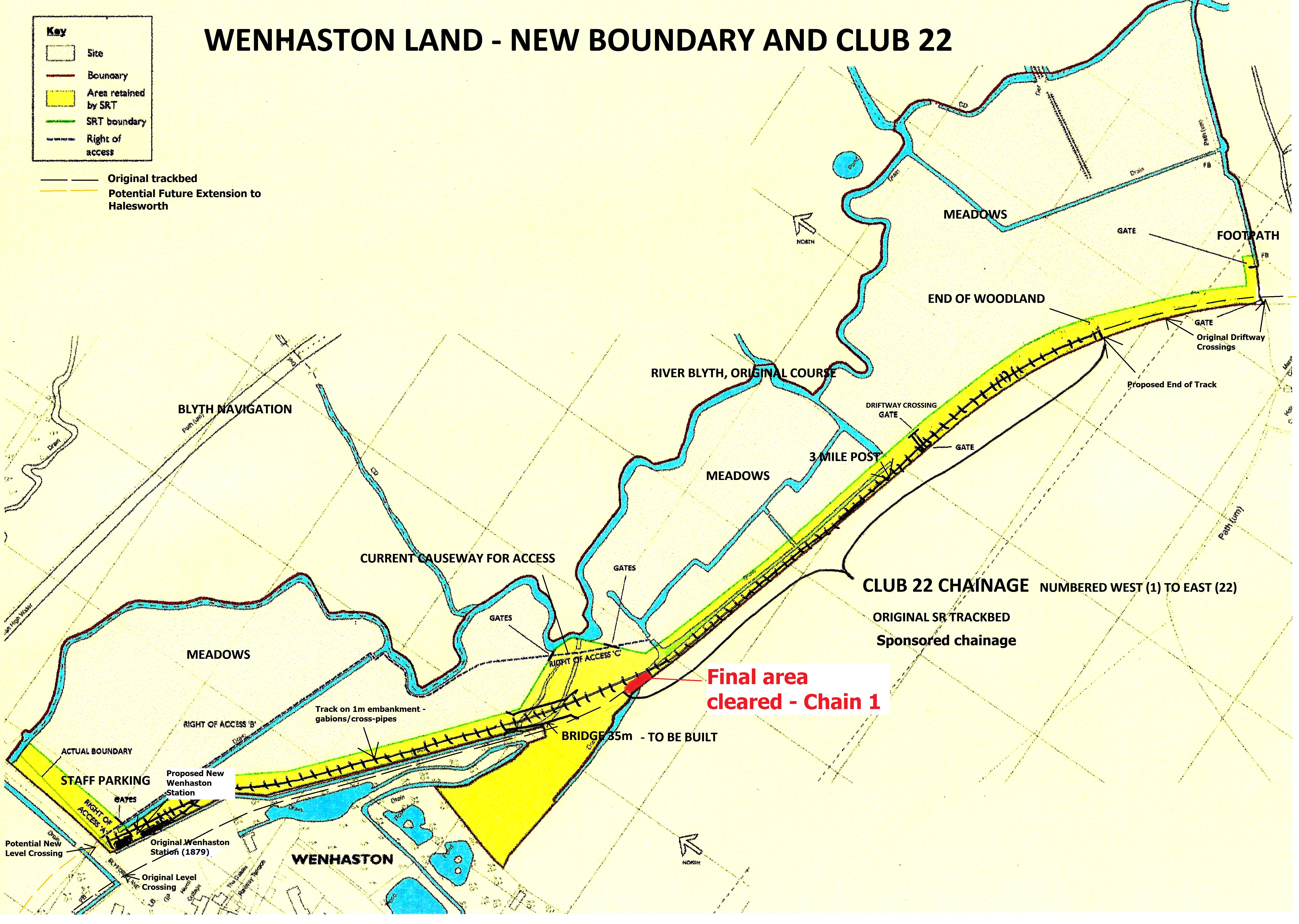

The Southwold Railway Trust can look backward to 2015 as a good, but hard, year of consolidation. Our volunteers spent almost six months on two efforts – firstly, works to enable the boundaries and access on the Wenhaston land, including