It was so fine on Wednesday 25th February that Bob, Toby and John B decided to carry on painting the grounded van body at Wenhaston station – having had a glimpse of the maroon finishing coat from a passing bus, I can vouch for its effectiveness, and ability to sit within the landscape as if it had always been there. On the following Saturday, Toby finished the job.

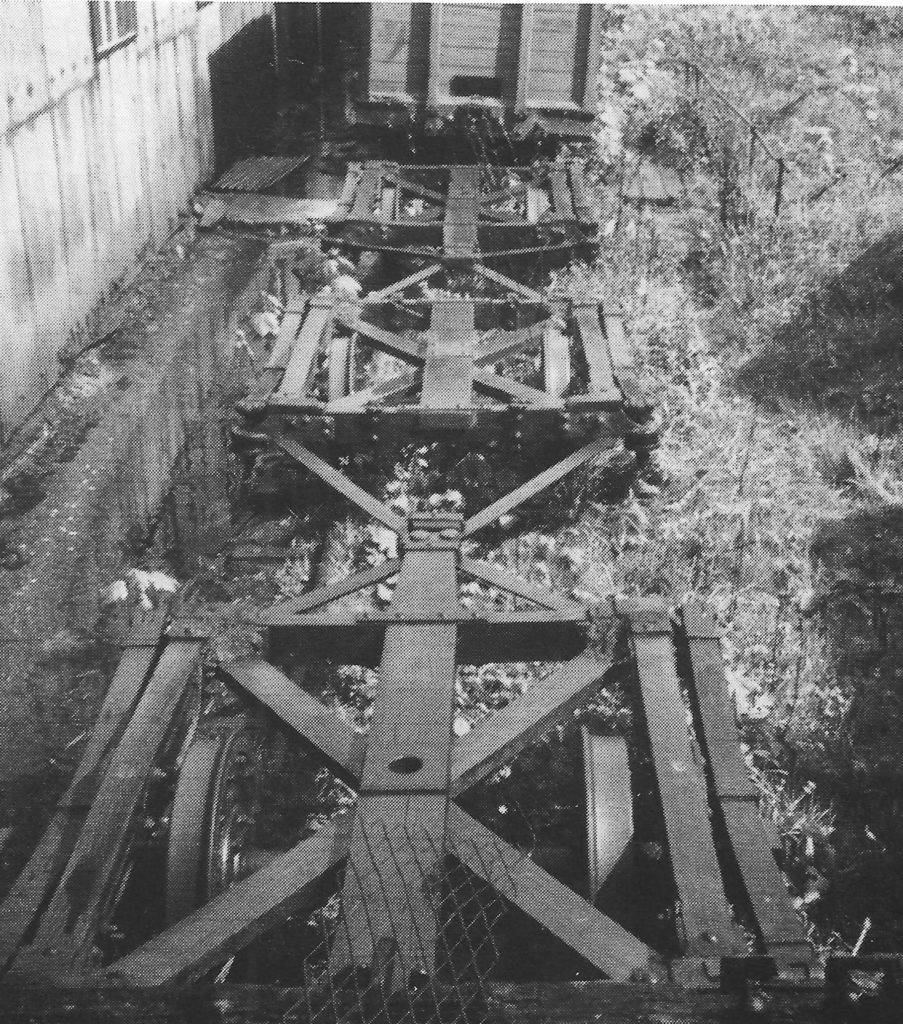

The rest of the team worked on the Motor Rail loco, as well as continuing preparation for our SR balcony coach replica no 8. In connection with the design of the working underframe for the coach, we comprehensively measured and photographed the Manx Northern Railway coach’s Cleminson and its brake gear: although the dimensions of the coach and underframe vary from the SR, we can extrapolate from one to the other, thus preserving the geometry of the system. (Further information about John James Davidge Cleminson’s Patents can be found online, with the surprising fact that he and his Patent witness Percy E Mattooks were living at: “2 Popers Head Alley, Oornhz’ll, London” – an address either strangely Dickensian or just not clearly written [Cornhill?]) We should now have enough information, when collated and drawn, to allow for the SR coach underframe (both fixed and flexible) to be designed. The brake gear is inevitably complex – but little more so than similar gear on a bogie coach.

Meanwhile, our electrical specialist John R was delving into the mysteries of the Motor Rail control panel, which he has released from years of rust on the cab front: only a small number of the many wires (which I must say make me twitch just to see, not being of an electrical turn of mind) are identified and/or colour coded, so John will start at the beginning, identifying, testing and labelling as he goes. On Saturday John identified all the wires neatly, and removed the complete assembly from the bulkhead: he can now replace the aged components, and the bulkhead can be painted before it all goes back.

Chris carried on – and with an exclamation of triumph finally finished – removing the remainder of the brake gear. This has now been cleaned up, de-rusted, and primed, ready for re-assembly, when we have had the missing pins, clips, and shafts made. After a lift onto blocks on

Saturday, we had a go at removing the wheels (for re-gauging), but

were not overly surprised when they refused to budge – a very heavy duty

hub puller is called for now. The central portion of the underside of

the vehicle – the final drive – is now exposed, and can be cleaned up

and checked (though apart from being very oily, it looks good).

On Saturday, Richard put the control system back together after every

part had been refurbished – oddly, although everything moved happily

before this, the whole thing was in some mysterious way constrained when

it was all in one piece – something for another day. Various components

are now resplendent in JCB heat-resistant yellow, and we made a trial

of the newly-acquired Williamson’s paint – undercoat for GER Blue – on

wheel retainers and part of the body. It’s certainly a joy to work with,

and covers beautifully.

A local supporter has given us an oil drum, so James had a noisy but

satisfying half hour with a cold chisel and heavy hammer, cutting the

top

out, and piercing the base, to provide a second incinerator for Wenhaston.

In the intervening parts of the day, various components were cleaned up,

de-rusted, and in some cases painted in yellow. One of our newer

volunteers – another John, hereinafter John H – worked on removing the

brazed-in flexible exhaust section from its housing, as a rest from

clambering around under the MNR coach with a tape measure. We ended the

day with a lift, getting the very heavy and awkward second

coupling/dragbox assembly onto the workbench ready for clean-up,

de-rust, paint and lubrication – a job begun on Saturday. The coupling

height is a little low, but the thought of drilling ¾” holes through an

inch of steel twelve times, and having to modify the coupling housing in

such a way that the fixing bolts will not be completely inaccessible –

and also

having to remove impossible-to-reach high-tensile locking nuts – has led the team to apply a little pragmatism – the Motor Rail buffers will be at a slightly different height from the wagons, and longer hooks (neither of which we have, anyway) will be provided. Sometimes even the SRT has to compromise!